Flag factory with a digital showcase

We are a flag and flagpole factory without a fixed and heavy company structure. This allows us to streamline processes and reduce costs in order to offer the most competitive prices on the market to our distributors.

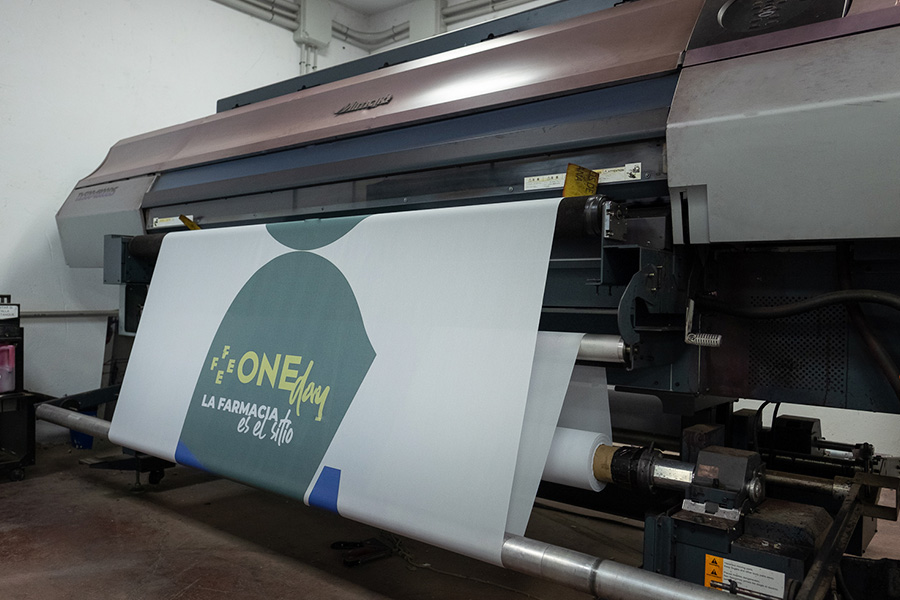

Digital flag printing machine room

We print on Mimaki machines with official and ecological inks:

- Inkjet and sublimation printing

- CMYK colours (four-colour process)

- With a colour transfer of approx. 96%.

This printing technology is specially designed for high quality colour application.

This technique requires a type of banner fabric that ensures a higher quality in printing than conventional ones, so the composition of the fabric we work with has the following characteristics:

- 100% polyester fabric of 115 g/m2 and 180 g/m2.

- Weaving: 50% weft and 50% warp and three-thread mesh.

- Air permeability: 2050 L/m2.

- Tolerance in dimensions: + 5%.

- Shrinkage when washing at 40ºC: Length: -1,5% Width: -1%.

- Anti-pollution surface treatment.

Our manufacturing process makes our flags more resistant to water, air, sunlight and friction. In addition, they are washable without fading, allowing for easy maintenance and conservation.

Dressmaking and sewing workshop

Once the flags have been printed, they are checked to ensure that the design has been correctly created and are then passed on to the sewing and dressmaking workshop. In this room, the rolls of fabric are cut according to the characteristics of each type of flag.

After the flags have been cut, they are sewn using industrial sewing machines (Brothers, Sewmaq, Jack y Siruba Brands)

All of them with two needles, with a 14mm double feed separation between them.

Together with the experience of our sewing professionals, the garment is finished with the following characteristics:

- A backstitch stitching with special thread.

- Double hem with a width of 10 mm.

- 7 mm symmetrical double seam (1.5 mm from the edges).

- Stitch width: 5mm.

Packaging and shipping

Once the flag has been finished, the order is packed and prepared with the accessories selected by the distributor.

With the strapping machine, the package is protected so that the contents are not damaged during transport.The order is then placed at the disposal of our courier service providers, who will deliver it according to the method selected on the website either conventionally or by dropshipping (delivery to your end customer with the distributor as the sender).

The human capital of our company

We are so cheap because our distributors only pay for printing, sewing and packaging. 100% of our workers are printers, seamstresses or logistics workers.

We don't have a single commercial worker, accountant, designer, collection worker, administration worker or any other worker who doesn't add value to the distributors.

Benefits of becoming a distributor

Free samples and catalogues

Save carts online

Exclusive discount for distributors

Real-time pricing and order tracking

Access to invoices and print designs

Delivery methodology & timmings

Secure payment

If your customer is not happy with the flags, you always get your money back.

How do we work in 1 minute?

Our main goal is to make our distributors to sell more flags in the easiest possible way with a higher profit margin. That´s why we offer:

- A 100% online sales channel.

- Exclusivity to professionals. We never sell to end customers.

- A manufacturing and delivery time of 24 hours in almost all countries across Europe.

This is the reason why we achieve:

- A considerable cost savings that allow us to offer the cheapest prices and increase the profit margin of our distributors.

Customised flags factory

As we are manufacturers, we make 100% personalised flags for our distributors. We offer flag finishes that include possible combinations of: rings, sheaths, ribbons and cords, eyelets, Velcro, different sewing finishes...

The combination of these finishes allows the flag to be customised to the required tastes and needs.

As a whole, these printing and manufacturing techniques make the flags we produce more resistant to water, air, sunlight and friction. In addition, they are washable without fading and their maintenance and conservation are very simple.